Infrared curing technology revolutionizes auto body shops and paintless dent repair by speeding up and improving coating hardening, offering precise temperature control, and ensuring consistent results on various surfaces. Accurate infrared curing equipment calibration is essential for maintaining quality, with regular checks, controlled environments, preventative measures, and staff training minimizing deviations from optimal settings, thereby enhancing finish consistency in vehicle restoration and collision repair services.

In today’s advanced manufacturing landscape, paint shops rely on precision with every coat they apply. This is where infrared curing equipment comes into play, offering efficient drying and curing solutions. Understanding how these machines work is crucial for achieving accurate results. This article delves into the intricate process of calibrating infrared curing equipment to ensure optimal performance. From comprehending the technology to implementing best practices, we explore the key steps for maintaining consistent and precise results in paint shop operations.

- Understanding Infrared Curing Technology

- The Calibration Process: Ensuring Precision and Consistency

- Best Practices for Maintaining Accurate Infrared Curing Equipment

Understanding Infrared Curing Technology

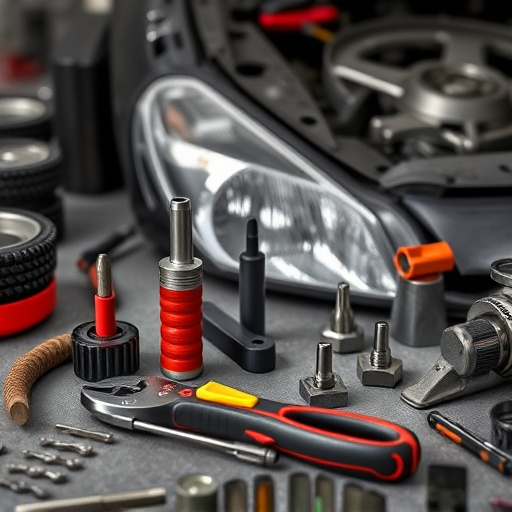

Infrared curing technology has revolutionized various industries, including automotive body shop services and paintless dent repair. This innovative process utilizes infrared radiation to cure or harden coatings, adhesives, and sealers quickly and efficiently. Unlike traditional curing methods that rely on ambient air circulation or UV light, infrared curing equipment offers precise control over the curing process. By emitting specific wavelengths of infrared energy, these machines ensure optimal temperature distribution, allowing for faster drying times without compromising the quality of the finish.

Paint shops that specialize in body shop services often employ infrared curing equipment to enhance productivity and accuracy. The technology’s ability to penetrate materials quickly makes it ideal for various applications, from coating hard-to-reach surfaces to curing complex multi-component systems. Additionally, infrared curing ensures consistent results, minimizing the risk of uneven drying or surface imperfections that can occur with other methods, thus elevating the overall quality of the final product in automotive body shop services and paintless dent repair.

The Calibration Process: Ensuring Precision and Consistency

The process of calibrating infrared curing equipment is a meticulous one, designed to ensure precision and consistency in auto body services. It involves a series of steps where trained technicians carefully adjust and test the equipment’s settings. This is crucial as even slight variations can impact the quality of paint jobs, leading to either over-curing or under-curing, both of which can compromise the final finish.

During calibration, various parameters are checked and fine-tuned. This includes adjusting temperature control to maintain optimal heat levels for different types of paints, ensuring uniform exposure across the entire surface, and setting precise timing sequences to match the specific drying requirements of each auto body services application. Regular calibration not only guarantees the accuracy of the infrared curing equipment but also contributes to the overall quality and longevity of the paint jobs in body shop services.

Best Practices for Maintaining Accurate Infrared Curing Equipment

Maintaining accurate infrared curing equipment is paramount for achieving consistent results in auto collision repair and vehicle restoration processes. Paint shops should establish regular calibration schedules to ensure the equipment’s performance aligns with manufacturer specifications. This includes routine checks of temperature control, power output, and timing functions. Utilizing specialized calibration tools and following recommended maintenance protocols are best practices that significantly reduce deviations from optimal curing parameters.

Moreover, a clean and controlled environment is crucial for maintaining infrared curing equipment precision. Preventative measures such as regular filter changes, dust removal, and shielding from external heat sources can minimize the buildup of contaminants that may skew readings or cause performance issues. Proper training of staff on best practices for handling and operating the equipment also plays a significant role in preserving accuracy, ensuring consistent quality in car repair services and vehicle restoration projects.

Infrared curing equipment plays a pivotal role in modern paint shops, offering precise and efficient drying solutions. Calibration is the key to ensuring these systems deliver consistent performance, which is why understanding the calibration process is essential for maintaining accuracy. By following best practices, such as regular maintenance, monitoring environmental conditions, and adhering to manufacturer guidelines, paint shops can maximize the benefits of infrared curing technology, resulting in high-quality finishes and increased productivity.